12 Practical Ways to Use Shipping Containers at Events

Over the last few years, temporary event infrastructure has changed its face. Today, organizers ask for a solid set up which are fast to deploy, reliable for bad weather, visually appealing, and highly efficient to reuse. Shipping containers fit that engineering brief well: they’re modular steel structures with predictable dimensions, excellent stacking strength, and a global ecosystem of parts and fabrication know-how.

In the 12 ways of shipping containers, we will help you assess how they can be moved with standard equipment, adapted off-site, and installed with minimal disruption on location. For many teams, a versatile shipping container for events approach makes it possible to launch pop-ups, brand experiences, and service zones faster than traditional temporary builds.

Shipping Containers Work Perfectly For Events!

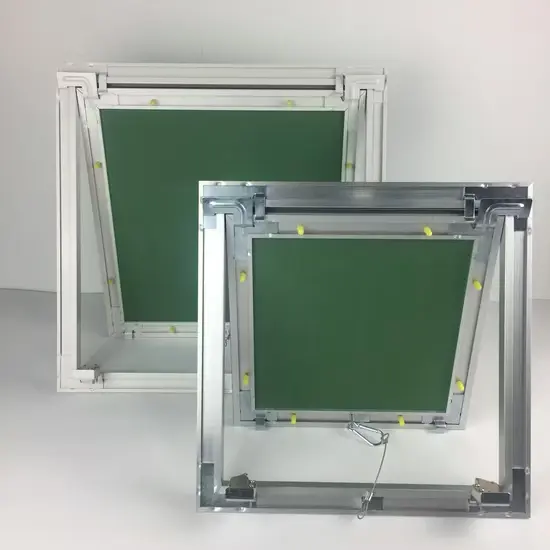

From an engineering view, containers work as standardized building blocks. Loads transfer through corner castings, so lifting and placement are reliable. You can cut walls into doors, hatches, windows, and ventilation in case of well-reinforced openings. Professionals also choose off-site fit-outs to reduce on-site labor and time risk. Remember that you can easily reuse a well-designed unit across multiple venues and seasons. You’ll only need to make minor changes. This ultimately improves ROI and reduces waste.

Consider The Following Attributes Before Choosing a Container Setup

| Core Area | What It Covers | Estimated Range (USD) |

| Delivery and placement | Transport and tilt-bed/crane/forklift as needed | $700–$6,000+ |

| Site prep | Leveling, gravel, mats, basic supports | $300–$3,500+ |

| Power and HVAC | Electrical tie-in or generator + cooling/heating | $600–$6,000+ |

| Water and waste | Water supply, tanks, pump-out (if required) | $200–$2,000+ |

| Connectivity | POS internet + attendee engagement Wi-Fi | $50–$400 |

| Permits and safety | Permits, egress, rails/stairs compliance, fire-safe finishes | $300–$3,000+ |

You must plan for the basics because sometimes even the strongest container idea falls short due to missing points. Ensure these points to ensure perfect execution of the plan!

- Confirm the site alignment with delivery handling and placement.

- Ensure that the ground and setup match the container’s footprint and expected loads.

- Align utilities, including power capacity and climate control. This means understanding taht how the unit will actually operate during peak traffic.

- Above all, keep an eye on permits and safety requirements from day one. This ensures that every point, including interiors, exits, stairs, and railings meet local rules.

Common Shipping Containers Applications

1) Ticketing and Check-In Booth

A container can operate as a secure ticketing hub with controlled entry points, protected equipment storage, and weather-resistant service windows. Engineers often specify pass-through openings with reinforced frames, integrated cable management, and counter surfaces that handle high throughput if you expect queues, plan for external canopy coverage, stanchion anchoring points, and clear sight lines for staff.

2) Box Office and Will-Call Storage

Will-call operations require organization and security. The option of containers stands out here becuase you can fit them with lockable shelving, internal workstations, and climate control. All this is beneficial to ensure the safety of printed materials and devices. While using this, you should access control and interior lighting levels; it is helpful for verification of accuracy. This also ensures a layout that separates customer interaction from secure storage.

3) Pop-Up Retail Shop

Container retail is popular because the shell naturally supports a controlled storefront experience. When you choose opening panels, they can become a shade. And in the case of interior fit-outs, you can experience permanent retail with slat walls, racks, and display lighting. As per key engineering points, you should focus on ventilation, thermal comfort, and power distribution (particularly when running digital signage, checkout stations, and feature lighting).

Read More: What is the Average House Exterior Painting Cost in 2025‑2026?

4) Merchandise Fulfillment and Inventory Back-of-House

The second container can function as a back-of-house inventory unit. This reduces restocking delays and reduces loss. What should you do? Where allowed, design for pallet access withclear aisle widths and solid flooring. In case of high volume event, include a small staging area. This will serve for pre-packed orders and controlled staff-only services.

5) Food Service Kitchen or Prep Unit

Do you know that you can adapt a container into a compact kitchen or prep unit? This option is common among festivals and stadium-adjacent activations. While considering this option, you should be focused on careful mechanical and safety design. This means well-dealing with commercial ventilation hoods, fire suppression (where required), non-slip and cleanable surfaces, grease management, and correct electrical capacity for appliances. Furthermore, you should plan the workflow so there is no conflict between raw and finished food paths. Above all, include handwashing and sanitation points where safety regulations apply

6) Beverage Bar and Serving Counter

A container bar can be fast, stylish, and operationally efficient. Serving hatches should be sized for peak demand, with reinforced frames to handle repeated use. As per professionals, general-purpose access doors are good in this case. As cold stoarges offer limited factors, considering undercounter refrigeration, keg storage, and insulated wall assemblies makes sense. Remember to deal with drainage and spills, considering that sloped floors and easy-clean finishes reduce downtime.

7) VIP Lounge or Hospitality Suite

When VIP hosting is the target, containers come as an ideal option as they provide privacy, branding control, and a secure footprint. You can also make upgrades in them, including acoustic treatment, HVAC, upscale finishes, and lighting zones. Furthermore, ensure to handle the structural design if you add a rooftop deck.

8) Brand Activation and Product Demo Lab

If you are working with tech products, automotive components, sports gear, or interactive exhibits, you can transform containers into a controlled demo environment. Engineers offer built-in power, data cabling, mounting points, and controlled lighting containers. In case of screens or VR setups, remember to plan for heat loads, cable routing, and backup power. This will help you avoid interruptions.

9) Stage Support, DJ Booth, or Control Room

Do you know that production hubs use containers for sound, lighting, and show control? They use them because they can easily add outfitted equipment racks in them. Furthermore, the team can improve isolation by using layered assemblies and sealed penetrations. Above all, a clean organization comes; that includes dedicated circuits, labeling, ventilation for heat-producing gear, and sufficient desk space for operators.

10) First Aid, Security, or Command Center

Events often need a visible, durable command post. You can configure containers as first-aid rooms, security offices, or multi-agency coordination centers. When targeting this, you should consider privacy partitions, internal communications infrastructure, secure storage for medical or security equipment, and controlled access points. Set Exterior signage and lighting in a way that makes the unit easy to find, whether day or night.

11) Restroom, Changing, or Shower Facilities

No doubt, portable restroom trailers are common. But container-based facilities are a solid alternative when you desire durability and reusability. This application depends heavily on plumbing. Therefore, you should be focused on water supply, waste management, ventilation, and winterization systems (if applicable). Also, go with moisture-controlling materials and ensure that the layout supports easy cleaning and maintenance. You can add ADA-accessible options where required.

12) Modular Green Room or Staff Break Area

You can effortlessly improve staff performance by providing them with a place to reset. When hitting this, you can use containers as they can be used as a break room, green room, or volunteer hub with seating, charging stations, lockers, and basic food storage. Regarding design, there is a need for airflow, lighting comfort, sound control, and enough outlets. This will prevent unsafe power-strip overloads.

Engineering Tips to Make Container Event Builds Safer and More Reliable

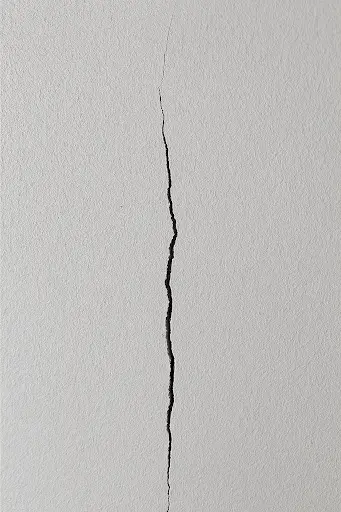

- Reinforce modified openings properly. Cutting large sidewall sections changes the container’s structural behavior. Reinforcement frames, header beams, and corner continuity should be designed with load paths in mind.

- Plan HVAC early. A steel box heats quickly in the sun and loses heat fast in cold. Insulation, ventilation, and correctly sized HVAC are often what separates a cool idea from a comfortable, usable space.

- Design for rapid deployment. Use standardized connection points, protected utility inlets, and clear lifting instructions. The less improvisation on-site, the smoother the install.

- Prioritize crowd flows. Service window height, queue direction, entry/exit separation, and visibility for staff all affect throughput and safety. Use cubic yard measurements for a better assessment.

- Use durable, event-friendly finishes. High-traffic spaces need scuff-resistant surfaces, easy-clean flooring, and protected edges. Small details reduce maintenance during the event.

The Bottom Line

Containers make sense when you plan the setup with considerations on logistics, utilities, and safety requirements. They work for all, from small local gatherings to multi-city tours.

Start with the site plan and access routes, because delivery and placement constraints often shape the entire design. Next, ensure power, HVAC, and any plumbing setup, as they ensure compliance with local codes. Last, opt for the best modular features: service hatches, removable stairs, or swappable interiors. This way, you can reuse the same setup for another venue.

And if you avoid all this hassle, call us for assistance! We will give you better options with estimates, ensuring you stay within budget and timelines without affecting quality.