How to Identify Poor Quality Electrical Wire and Cable?

Have you ever heard about a fire burst due to an electric shock? Undoubtedly, it is something that can cause significant destruction. But what’s the reason behind it? Is it due to bad wiring or lousy wire quality? Both can be the reason behind the tragedy.

Therefore, ensuring the excellent quality of wire and cable for house electrical wiring is essential. But how to identify poor quality electrical wire and cable? Expertise and knowledge are needed to determine the quality of electric wires and cables.

Let’s uncover some beneficial points to answer how someone can identify the quality of wire and cables!

Two Major Types of Electrical Wires

Before exploring ways to identify bad-quality electrical wires, we must understand different types of electrical cables. It would help us highlight the excellent quality and choose the best option for the particular electrical project.

1. Copper Wire

The most common type of cable we use to satisfy our daily needs is electrical copper wire. It is famous for optimal performance and high conductivity. Unlike other metals, it is highly stretchable and needs less insulation.

Types of Copper Wire

| Sr No. | Type | Specifications |

| 1. | Copper Bare |

Applications: Jumpers Electrical hookups Electrical appliances Electrical systems grounding |

| 2. | Copper Tin Plated |

Applications: Water treatment Desalination Power generation Chemical processing |

| 3. | Copper Wire Plated with Nickel or Silver |

Applications: Aerospace Defense systems Petrochemical Nuclear industry Medical applications |

| 4. | Oxygen-Free Copper Wire |

Applications: Automotive appliances Industrial applications Electrical applications |

| 5 | Copper Clad Steel (CCS) |

Applications: Hardware Temperature measuring machines Medical products Intelligent pressure Motors Magnetic assemblies Power supplies |

| 6. | Copper Clad Aluminum (CCA) |

Applications: Voice coils Headphones Portable loudspeakers |

| 7. | Copper Alloy |

Applications: Power generation Power transmission Telecommunications Electronics circuitry Power distribution |

Silver Electrical Wire

Another name that people use with copper electrical wires is silver wires. It is also a good conductor of electricity. On the scale, copper ranks 97, while silver ranks 100.

In old times, experts used it for making vacuum tubes. Even today, we use silver for semiconductor devices, circuits, and their components.

All the credit goes to its good conductivity and suitability for a vast range of electrical appliances. Let’s explore the top 10 types of electrical wires other than copper and silver!

Also Read : What is Elemental Cost Analysis?

Top 10 Types of Cable

| Sr Num | Cable | Specifications | Type |

| 1. | Panel Wire Cables | It is the best quality cable for electrical control panels. The option offers safe and easy installation. |

|

| 2. | PVC Power Cables / XLPE | The best option for industrial electrical installation is shaped in stranded copper conductors. Its rated temperature is 70℃; however, the rated voltage is 600/1000V. Moreover, it is PVC bedded with PVC compound-insulated flame retardant. |

|

| 3. | Armored Cables | It suits mechanical projects since engineers tape it with aluminum or steel wire. Its maximum operating temperature is 90°C while its minimum bending is 0°C. |

|

| 4. | Rubber Cables | It can work perfectly at high temperatures and wet conditions, which means it is highly resistant to oil and flame. Furthermore, it is a good option for giving polymers effective insulating properties. |

|

| 5. | LSHF Safety Cables | LSHF stands for “Low Smoke Halogen Free.” It is a type of electrical cable that is entirely halogen-free and emits very low corrosive gasses and smoke when a fire bursts. |

|

| 5. | Fire Resistant Cables | It has self-extinguishable properties that make it perfect for stopping fire spreading. Moreover, it contains 26% indexed oxygen. The standard demand for index oxygen is 21%. Its most prominent application is emergency circuits. |

|

| 6. | Screened / Control Cables | Engineers design it for small household appliances. Its primary application is mobile installation. |

|

| 7. | Instrumentation cables | In industrial installations, experts use these cables for transmitting electrical signals. It is the best option for optimum data transmission. |

|

| 8. | Solar Cables | Cables are suitable for interconnecting photovoltaic panels. It is compatible with DC and AC inverters. The line is highly resistant to extreme temperatures and solar radiation and thus can be installed outdoors. | — |

| 9. | Special Cables | Engineers create special cables for unique installations, such as purification and cleaning systems, |

|

| 10. | Aluminum Cable | Whether you deal with electrical installation for indoor, outdoor, or underground projects, aluminum cables suit all. They are compatible with power transmission. |

|

Factors to Consider When Checking the Quality of Electrical Wires

Judging the quality of the wire is essential to ensure the flawless transmission of electrical energy.

Following are some factors one must consider when checking the quality of electrical cables. You can also use these factors to identify poor quality electrical wire when finding the best one in the market.

1. Brand

Suppose you don’t even know the ABC of electrical wires. How can you detect the quality of cable?

You can consider the brand name when you want to choose the excellent option. Like restaurants, ranking and reputation work in the electrical industry. Thus, you can check the brand name to know whether you should buy from the shop.

2. Packaging

Packaging of the product sometimes reflects the quality of the cable or wire packed inside the box. Therefore, you can identify poor-quality electrical wires by seeing the product packaging.

Following are the some features that decide the poor quality packaging:

- Extra small or large box size

- Poor packing material

- Odd shapes

- Use of odd visuals

- Excess wrapping

- Use of weird colors

3. Quality (Weight, Length, & Cross-Section Area)

You can detect the product quality by checking the weight of the item. It decides the quality of cable or wires packed inside the box.

For example, the standard weight of 100 m long and 1.5 mm² plastic insulated single-strand copper core wire is 1.8~1.9 kg. Similarly, the 100 m long and 2.5 mm² plastic insulated single-strand copper core wire weighs 2.8~3.0 kg.

If the supplier is equipping you with products with lower weight, it must be poor-quality electrical wire or cable.

The same is the case with electrical wires’ length and cross-section area.

4. The Strength

Specialists recommend repeatedly bending the wires at the cable’s head point. It decides the quality of the product by showing the soft or hard touch, good or bad fatigue resistance, high or low elasticity, and wire cracks.

The product, with a soft touch, enough fatigue resistance, high elasticity, and no cracks, is of superior quality.

Engineers do different tests to check wire quality using the strength concept. These tests include:

- Tensile tests

- Fatigue tests

- Hardness tests

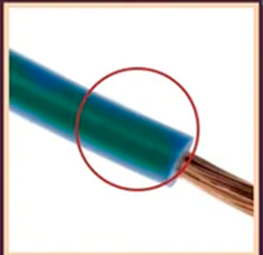

5. Insulation Material

People mostly go for thick insulation. Is it really good? Not at all, actually.

Wire and cables with extra-thick insulation are more susceptible to easy tearing due to low flexibility. Manufacturers mainly produce it using recycled plastic, the primary reason behind its quick whiteness and powder fall-off.

So, one must go with quality and long-lasting insulation.

6. Copper Color

The electrical wire with a copper color other than shiny purple-red is of poor quality. Whether it is black-red or yellowish, the equality of cable is poor.

With the change of color, the product will also give a hard and rough touch.

Tips On How to Identify Poor Quality Electrical Wire and Cable Visually

When there are multiple options available on the table, you must be careful in your choice because a little mistake can let you buy poor quality wire.

Following are some visual points you must consider to avoid making this mistake.

| Poor Quality | Good Quality |

|

Plain white packaging WITHOUTUL holographic sticker. |

Plain white packaging WITH UL holographic sticker |

|

Cable WITHOUT UL Marking. |

Cable WITH UL Marking |

| WITHOUT Length Markings

|

WITH Length Markings

|

|

Different shades WITHOUT proper printing |

Variable shades WITH proper printing |

| DIFFERENT shades in cable

|

SAME shades in cable

|

| IMPROPER cable covering

|

PROPER cable covering

|

|

Immediate marks of DAMAGE |

FLAWLESS wire and cable

|

| BREAKABLE jacket after 2-3 folds

|

UNBREAKABLE jacket even after 2-3 folds

|

Hire Professionals to Differentiate Between Poor and Good Electrical Wire and Cable

Contractors and builders mostly get assistance from estimators to calculate the electrical project budget. During electrical estimating the budget, they consider all these factors to always go with the most reliable electrical cable and wire option.

Professionals help them choose the best quality at a reasonable cost because they understand that money does not always buy the quality.

Therefore, getting assistance from industry specialists is better. With their assistance, you can easily bypass poor-quality electrical wires and always choose the best cable for electrical signal transmission.

Bottom Line

The market is loaded with various electrical wires and cables. Some are of high quality, while some offer poor performance. It is challenging how to identify poor quality electrical wire and cable.

One can consider some factors to determine the good and the wrong wire or cable. These factors include brand, insulation material, packaging, height, weight, size, strength, and copper color. You can also see the wire to check precise tagging, proper printing, flawless manufacturing, shading, and jacket covering.

These factors can help you choose the best product and avoid poor quality efficiently. You can also get assistance from electrical estimators, get valuable suggestions, and go with the perfect quality according to the nature of your project.

FAQs

Why is detecting the quality of the wire essential?

Detecting the quality of wires and cables is essential to avoid short circuits and prevent fire. Whether it is residential, commercial, or industrial, a little ignorance in this matter can put your family and co-workers at a life-threatening risk.

What decides if the wire is of low quality?

The following are the factors that decide the wire is of low quality:

- Low flexibility

- Poor packaging

- Odd dimensions and weight

- Thick layer of insulation material

- Changed color of copper-coating

Which wire is best for wiring purposes?

There are two options you can choose for wiring: copper and aluminum. And if you want to be more specific, copper is the best option for wiring.